- Written By Team DWS

- Jewelry Manufacturing

- February 11, 2026

Precision and Passion: The Manufacturing Techniques Behind DWS Jewellery

Every extraordinary piece of jewelry begins not with gemstones or gold but with an idea — a concept born from imagination, refined by skill, and perfected through precision. At DWS Jewellery, this transformation from vision to reality is fueled by equal measures of passion and technical expertise.

Based in the vibrant city of Jaipur, Rajasthan, DWS Jewellery has earned global recognition for its exceptional craftsmanship, innovative manufacturing, and ethical production practices. From high-end fine jewelry to bold fashion collections, every DWS creation reflects an unwavering commitment to quality and artistry.

In this behind-the-scenes exploration, let’s uncover how DWS Jewellery merges traditional techniques with modern technology to manufacture pieces that embody both timeless beauty and engineering perfection.

The Heart of DWS Jewellery: Where Art Meets Engineering

For DWS Jewellery, manufacturing is not just a process — it’s an art form built on precision, patience, and passion. Every step is guided by a philosophy that believes true beauty is found in the details.

Whether a piece is handcrafted for a boutique brand or mass-produced for global retail, the same attention to craftsmanship is maintained. What differentiates DWS from others in the industry is a seamless integration of manual artistry and mechanical innovation.

At the core of our operations lies a conscious blend of:

- Heritage craftsmanship inherited from Jaipur’s ancient jewelry traditions.

- Cutting-edge manufacturing technology that ensures accuracy and scale.

- Ethical and sustainable production practices aligned with global standards.

This triad allows DWS to serve diverse international markets while remaining deeply rooted in India’s jewelry-making legacy.

________________________________________

Step 1: The Design Process — Where Imagination Takes Shape

Every masterpiece starts with a concept. In DWS Jewellery’s advanced design studio, creativity thrives through collaboration between traditional jewelry artists, CAD designers, and gemstone experts.

Hand-Sketching the Vision

Some ideas begin the old-fashioned way — with pencil and paper. Skilled designers sketch initial concepts inspired by nature, architecture, fashion trends, or cultural motifs. These hand-drawn renderings reflect the human touch that gives jewelry its soul.

CAD Modeling for Precision

Once the design concept is approved, digital artists convert sketches into CAD (Computer-Aided Design) models. These 3D renderings allow precise control over proportions, symmetry, and structure, ensuring that the piece not only looks stunning but also remains wearable and functional.

CAD models serve as a bridge between art and engineering. They help:

- Visualize designs before production.

- Calculate metal weight and gemstone placement.

- Streamline prototyping and reduce errors.

Prototype Development

Using 3D printing and wax modeling, the design team creates tangible prototypes that allow clients, designers, and artisans to examine the jewelry before mass production. This stage ensures that aesthetics meet practicality — every curve, clasp, and contour is tested for perfection.

When creativity meets precision, the blueprint for brilliance is born.

________________________________________

Step 2: The Casting Process — Bringing Metal to Life

Once a prototype is approved, DWS moves into the casting stage — the transformation of design into tangible metal form.

Wax Tree Assembly

Multiple wax replicas of the jewelry piece are attached to a central wax stem, forming what’s known as a wax tree. This allows multiple pieces to be cast simultaneously, improving efficiency.

Investment and Burnout

The wax tree is placed inside a steel flask and filled with a plaster-like material called investment. Once the investment hardens, the flask is heated in a kiln, melting away the wax and leaving behind an exact negative mold of the jewelry design — a process known as lost-wax casting.

Metal Melting and Pouring

The real alchemy begins here. Depending on the design, precious metals such as gold, silver, or brass are melted in high-temperature furnaces and poured into the molds.

At DWS, modern induction melting and vacuum casting machines ensure that the molten metal fills every crevice without air bubbles, resulting in flawless metal structures.

Cooling and Breaking the Mold

Once cooled, the investment mold is carefully broken to reveal the raw metal casting. Each piece is then manually separated from the tree — the first glimpse of jewelry emerging from fire and precision.

This moment marks the birth of a masterpiece.

________________________________________

Step 3: Cleaning, Filing, and Assembly — Refining the Rough Beauty

After casting, the raw jewelry requires refinement to bring out its full beauty.

- Deflashing: Excess metal and casting residue are removed.

- Filing and Shaping: Artisans meticulously file the surfaces, smoothen edges, and adjust shapes for symmetry and comfort.

- Assembly: Multi-component jewelry pieces — like pendants, earrings, or necklaces — are carefully soldered together using high-precision laser welding techniques.

Laser welding ensures minimal heat damage, superior joint strength, and refined finishing — a key advantage at DWS’s technologically advanced facility.

At this stage, what was once a rough cast now begins to resemble real, wearable jewelry.

________________________________________

Step 4: Gemstone Setting — Adding Life and Color

No jewelry is complete without its sparkle. At DWS, gemstone setting is an art handed down through generations. Jaipur’s reputation as the global gemstone capital empowers DWS with in-house expertise across all aspects of gem cutting, polishing, and setting.

Gemstone Selection

Each gemstone — whether diamond, emerald, topaz, or turquoise — undergoes a strict selection process based on color, clarity, carat, and cut. In-house gemologists inspect, match, and calibrate stones to fit each design perfectly.

Stone Setting Techniques

Depending on design complexity and stone type, expert setters use multiple traditional and modern methods, including:

- Prong Setting: For maximum brilliance.

- Bezel Setting: For strong protection and a vintage feel.

- Pavé Setting: For luxurious sparkle.

- Channel Setting: For seamless alignment.

- Micro-setting: For ultra-fine designer jewelry.

Under magnified precision tools, artisans position each gemstone by hand — aligning them to perfection using microscopes and digital measurement devices.

This painstaking process can take hours or even days depending on the piece. But it is here that jewelry gains its character and radiance.

________________________________________

Step 5: Polishing and Finishing — Revealing Brilliance

Polishing transforms jewelry from dull metal into gleaming beauty. At DWS, multi-stage polishing ensures brilliance across every surface, curve, and contour.

Stages of Polishing

- Pre-polish: Removes scratches and imperfections.

- Mirror polish: Achieves the highest shine using fine polishing compounds.

- Texturing: Adds matte, satin, or artistic finishes for stylistic depth.

Advanced tumbling machines, soft brushes, and micromotor polishers are combined with artisan expertise to achieve a perfect finish.

Plating for Perfection

Depending on the design, pieces may undergo rhodium plating, gold vermeil coating, or antique finishes. These enhance color, durability, and corrosion resistance while providing desired aesthetic effects.

Quality at this stage defines the piece’s final luxury appeal — and DWS ensures each jewel leaves the workshop at its absolute best.

________________________________________

Step 6: Quality Control — The DWS Promise of Perfection

Every single jewelry piece passes through multiple layers of inspection before leaving DWS’s manufacturing facility.

Physical Inspections

Experienced quality controllers check for:

- Structural durability and fitting accuracy.

- Symmetry and uniformity in design.

- Proper gemstone placement and security.

Technological Testing

Using laser scanners, spectrometers, and magnified imaging, DWS verifies metal purity and gemstone authenticity.

Finishing and Packaging Checks

Before dispatch, each piece is polished again, cleaned ultrasonically, and packed carefully under eco-friendly, export-ready conditions.

Only once a piece passes all checkpoints does it earn the DWS Jewellery seal of authenticity.

________________________________________

The Technology That Drives Innovation

While traditional craftsmanship forms the foundation, DWS Jewellery thrives through advanced technology integration that boosts precision, efficiency, and innovation.

Key Technologies Used

- 3D Printing for Prototyping: Delivers accurate structural models.

- CNC Machining: Improves mold creation precision.

- Laser Welding & Engraving: Minimizes heat damage and adds intricate details.

- Electroplating Units: Ensures consistent finish and corrosion prevention.

- AI-Powered Quality Control: Detects asymmetry or surface flaws.

These technologies not only enhance productivity but also allow DWS to remain competitive in global markets by offering customization, scalability, and quality assurance.

________________________________________

The Human Element: Artisans Behind the Technique

Despite automation advances, the true soul of DWS Jewellery lies in its artisans. These highly skilled craftsmen and craftswomen embody Jaipur’s generational expertise in jewelry-making.

Their hands shape wax, mold metal, set stones, and polish every surface with precision born of passion. Many artisans have spent decades perfecting a single skill — engraving, setting, filing, or enameling — and it’s their dedication that infuses every DWS piece with life and character.

At DWS, artisans work side-by-side with digital designers and engineers, creating a rare balance between handcrafted tradition and factory-scale precision. This collaborative environment keeps the artistry authentic while meeting international demand.

________________________________________

Ethical and Sustainable Manufacturing

DWS Jewellery believes that true luxury cannot exist without ethics and responsibility. The company’s Sedex SMETA 4-Pillar certification reflects its ongoing commitment to labor welfare, environmental care, and sustainable production standards.

DWS Sustainability Practices

- Using recycled metals and eco-safe casting materials.

- Promoting fair wages and safe working conditions.

- Implementing wastewater recycling and energy-efficient systems.

- Supporting skill-development initiatives for local artisans and women workers.

By embracing sustainability as a core value, DWS contributes to a future where jewelry manufacturing is both beautiful and responsible.

________________________________________

Custom Manufacturing and Private Label Expertise

DWS Jewellery’s manufacturing process is not just about making jewelry — it’s about crafting brands. The company’s dedicated private label and custom manufacturing services allow designers, retailers, and global brands to collaborate and create exclusive product lines.

Whether the request is for luxury fine jewelry, bohemian artisanal creations, or commercial fashion pieces, DWS tailors its manufacturing process to meet each client’s market goals.

Services include:

- Product conceptualization and design assistance.

- CAD/CAM prototyping and sampling.

- Bulk manufacturing with consistent quality.

- Custom branding and packaging for export.

This flexibility makes DWS a trusted partner for clients in Europe, America, the Middle East, and Asia, looking to bring unique collections to life.

________________________________________

Innovation Meets Heritage: The DWS Difference

What sets DWS Jewellery apart isn’t just technical mastery — it’s the harmony between innovation and heritage.

In an age of mass production, DWS continues to uphold Jaipur’s legacy of handcrafted artistry while leveraging modern solutions for global markets. It’s a delicate balance — one that requires constant creativity, discipline, and an unshakable dedication to excellence.

Each step in DWS’s manufacturing process — from design visualization to final polish — reflects years of expertise, technological investment, and most importantly, love for the craft.

________________________________________

Looking Ahead: The Future of Jewelry Manufacturing

As jewelry trends evolve and sustainability becomes non-negotiable, DWS Jewellery continues to innovate with purpose.

Future-forward initiatives include:

- AI-driven design trend analysis for predictive jewelry creation.

- Blockchain-enabled sourcing for full gemstone traceability.

- Digital prototyping & virtual try-on technology for B2B clients.

- Eco-metal alloy experiments for low-impact luxury production.

DWS’s vision is clear — to remain a global leader in ethical, technologically advanced, handcrafted jewelry manufacturing.

________________________________________

Conclusion: Precision and Passion in Every Creation

Behind every gleaming DWS creation lies a story — of human hands that shape, machines that perfect, and a spirit that ignites brilliance.

Precision ensures structural excellence.

Passion ensures emotional connection.

Together, they define the essence of DWS Jewellery.

As the world looks toward more conscious luxury and meaningful adornment, DWS continues to lead by example — crafting beauty with technology, responsibility, and heart.

In every millimeter of polish, every gemstone glint, and every innovative technique, DWS Jewellery proves that perfection isn’t achieved once — it’s pursued every single day.

Popular on Blogs

Black Tourmaline: Meaning, Healing Properties, Fascinating Facts, Powerful Attributes, Versatile Uses, and Beyond

September 05, 2023 / BY Team DWS

Black Tourmaline, also known as Schorl, is a highly revered crystal with incredible metaphysical properties. It derives its name from the Dutch word "turamali," meaning "stone with ..

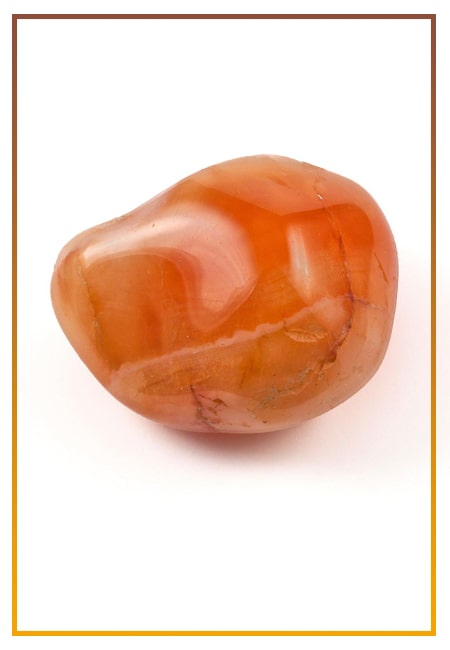

Carnelian Stone: Meaning, Healing Properties, Power, Facts, Color, Uses and More

December 26, 2023 / BY Team DWS

Carnelian is a vibrant and captivating gemstone that holds a plethora of meanings, healing properties, and powers. Its warm and fiery energy makes it a popular choice among crystal ..

Citrine: Exploring its Meaning, Healing Properties, Fascinating Facts, Powers, Versatile Uses, and Much More

November 18, 2023 / BY Team DWS

Citrine, with its warm golden hues, has captured the attention and imagination of people for centuries. This beautiful gemstone, commonly associated with wealth and prosperity, hol ..

Black Onyx: Unveiling the Meaning, Healing Properties, Fascinating Facts, Powerful Attributes, Versatile Uses, and Beyond

July 25, 2023 / BY Team DWS

Black Onyx, a striking gemstone admired for its deep black hue and elegant appearance, has captivated people for centuries. In this comprehensive guide, we will delve into the mean ..

The History Behind The Popularity of Red Agate

December 23, 2022 / BY Team DWS

An Agate is a type of magma rock that takes many years till it is washed out naturally into the water. And that is the reason this stone has elements of water. This beautiful stone ..

Unveiling the Mysteries of Turquoise Stone: Exploring its Meaning, Healing Properties, Power, Facts, Color, Uses, and More

December 05, 2023 / BY Team DWS

Turquoise, with its captivating blue-green hue, has been adorning jewelry and artifacts for centuries. This striking stone has a rich history, rich symbolism, and a plethora of int ..

Plan a Perfect Valentine's Week with Our Valentine Week List 2026

January 22, 2024 / BY Team DWS

Valentine's Day is undoubtedly the most romantic day of the year, but we believe that one day is just not enough to express your love and make your partner feel special. That's why ..

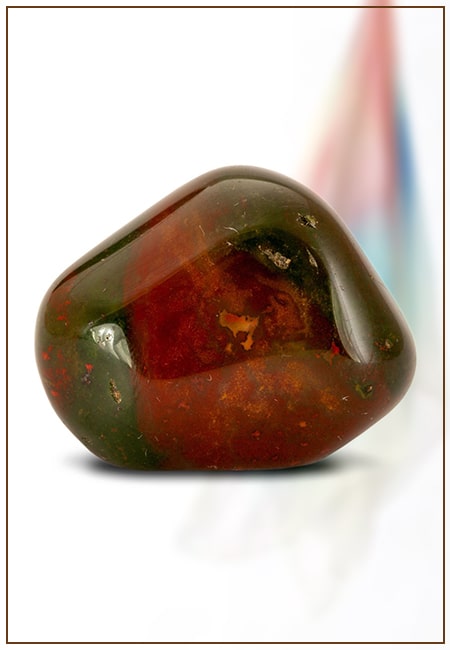

Bloodstone: Unveiling the Meaning, Healing Properties, Facts, Powers, Uses, and More

August 21, 2023 / BY Team DWS

Bloodstone, with its captivating deep green color with specks of red, is a mesmerizing gemstone that has fascinated civilizations for centuries. It possesses unique healing propert ..